Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

Regulation and certifications

Regulation FAQ

What do Standards, Regulations and Directives mean?

A standard

A standard is an initiative by market players and represents a reference framework designed to provide "guidelines, technical or qualitative prescriptions for products, services or practices serving the general interest". (according to Afnor, the French standards association). The decision to comply with a standard is always voluntary for a company and is intended to facilitate trade in a given field.

Regulations"Regulations are binding legislative acts. They must be implemented in full throughout the European Union". (www.europa.eu)

Examples:

The DOP (Declaration of Performance) is a regulation: Regulation EU/305/2011.

Regulation (EC) No 1935/2004 (or "Framework Regulation") of the European Parliament and of the Council of 27 October 2004 defines the general requirements that apply to materials and articles intended to come into direct or indirect contact with foodstuffs, food products and beverages.

A directive"Directives are legislative acts that set objectives for all EU countries. However, each country is free to develop its own measures to achieve them". (www.europa.eu)

What is ISO 9001?

ISO 9001 is a standard that defines the criteria and requirements for the organisation of a company in order to implement a quality management system. It provides a framework to enable companies and organisations to provide consistent products and services that meet the expectations of their customers or users. ISO 9001 can certify part of a company's activity or the activity of a company as a whole. It never certifies a product.

SYVECO has been ISO 9001 certified since February 2021.

What are 2.1, 2.2, 3.1 and 3.2 certificates?

Preamble: Standard EN 10204: 2004

This European standard concerns the safety of metal equipment and machinery when delivered. It is transcribed in certificates 2.1, 2.2, 3.1 and 3.2. These are control documents supplied to the customer.

What is a 2.1 certificate?

It is a certificate of compliance with the order, indicating that the products delivered comply with the order. It must be validated by the seller and/or manufacturer. We issue this certificate at the customer's request.

What is a 2.2 certificate?

It is a declaration of conformity to the order with non-specific test results issued by the manufacturer. The test procedures are not standardised and are specific to the manufacturer, and the test does not have to be carried out on the product delivered. We do not supply this document. Our COC (certificate of conformity) is a good alternative.

What is a 3.1 certificate?

This is a certificate of conformity to the order with specific test results. This certificate is linked to the chemical analyses and mechanical characteristics of the main components of the product in relation to the material batches (casting number or heat number). It is often referred to as the "material and test certificate" or formerly the CCPU (Certificat de contrôle du produit en Usine).

We can supply this certificate when it is available. There is a charge for this service. The request must be mentioned on the order placed with our sister companies. This operation involves recording the casting numbers when preparing the order and may result in additional processing time.

What is a 3.2 certificate?This is a stricter certificate of conformity to the order, with the results of specific checks. These checks are carried out during an inspection and are validated by an independent representative of the manufacturing department and a third party representative (from the buyer or one appointed by official authorities). This certificate is issued in the factory/foundry. We do not supply this type of certificate.

Summary of inspection documents acc. to EN 10204:2004

CE marking - Does it apply to my product?

CE marking (European conformity) was created as part of European technical harmonisation legislation.

The CE marking is neither a certification mark nor an indication of the geographical origin of the product.

It is a regulatory mark which does not imply that the product has been manufactured in the European Union, but that the product meets all the essential requirements of each of the directives applicable to it, and authorises the distribution and free movement of this product within the Union.There are 5 main directives specific to our fields of activity:

- The Pressure Equipment Directive (PED) (2014/68/EU),

- The ATEX Directive (2014/34/EU),

- The Low Voltage Directive (2014/35/EU),

- The Machinery Directive (2006/42/EC),

- The Gas Appliances Regulation (2016/426)

If a product is not subject to a European directive, CE marking is prohibited.

What does notified body mean?

A notified body (NB) is an independent inspection body responsible for issuing CE approvals for products (TÜV, Bureau Veritas, etc.). They are designated by a number specific to each CExxxx type body. This can be found on the marking of the products they have approved. Being NB with regard to the PED (DESP in French) does not automatically mean that you are also NB with regard to other Directives. The European Commission provides lists of NBs for each Directive. Please note: since the Brexit, the former NBs based in the UK are no longer recognised as such (e.g. Lloyds Register UK).

NBs are companies that can carry out other activities such as consultancy, training, inspection and verification, certification, auditing, labelling, testing and analysis.Some examples of Notified Bodies:

What is DOC?

The "EU Declaration of Conformity" must be completed by the manufacturer or, failing that, by the company introducing the product onto the European market. This mandatory document can only be drawn up if the product is subject to a European directive (or regulation), for example, article 17 of the PED. The DOC must include the very precise information listed in Annex IV "EU Declaration of Conformity", such as the product, type, manufacturer's contact details, etc.

For any product falling within the scope of a directive, it is compulsory to provide a DOC. This document is self-declaratory and is not necessarily drawn up by a notified body.Article 17

EU Declaration of Conformity

1. The EU Declaration of Conformity shall state that compliance with the essential safety requirements set out in Annex I has been demonstrated.

2. The EU declaration of conformity shall be drawn up in accordance with the model set out in Annex IV, shall contain the elements specified in the conformity assessment procedures provided for in Annex III and shall be updated continuously. It shall be translated into the language or languages required by the Member State on whose market the pressure equipment or assembly is placed or made available on the market.

3. Where pressure equipment or assemblies fall within the scope of several Union acts requiring the drawing up of an EU declaration of conformity, a single EU declaration of conformity shall be drawn up for all those acts. This declaration shall mention the titles of the Union acts concerned and the references of their publication.

4. In drawing up the EU declaration of conformity, the manufacturer shall assume responsibility for the conformity of the pressure equipment or assembly with the requirements of this Directive.ANNEX IV

EU DECLARATION OF CONFORMITY (No XXXX)1. Pressure equipment or assembly (product, type, batch or serial number):

2. Name and address of the manufacturer and, where appropriate, of his authorised representative:

3. This declaration of conformity is drawn up under the sole responsibility of the manufacturer.

4. Subject of the declaration (identification of the pressure equipment or assembly enabling it to be traced; an illustration may be attached if necessary for this identification):

- description of the pressure equipment or assembly,

- the conformity assessment procedure applied,

- for assemblies, the description of the constituent pressure equipment and the conformity assessment procedures applied.

5. The subject of the declaration described above is in conformity with the applicable Union harmonisation legislation:

6. References of the relevant harmonised standards applied or other technical specifications in relation to which conformity is declared:

7. Where appropriate, the name, address and number of the notified body that carried out the conformity assessment and the number of the certificate issued, and a reference to the EU type-examination certificate - manufacturing type, the EU type-examination certificate - design type, the EU design-examination certificate or the certificate of conformity.

8. Additional information:

Signed by and on behalf of:

(date and place of issue)

(name, position) (signature)

(if applicable, identification of the signatory with power to bind the manufacturer or its authorised representative)Source :

EU Declaration of Conformity, Chapter 3 Article 17 and Annex IV

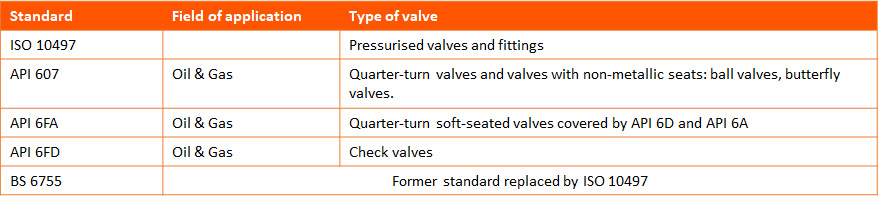

https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32014L0068What are usual standard for valves?

Take a look at our table of different standards:

What is PED - 2014/68/EUPED - Pressure Equipment Directive?

Access Multilingual Directive :

https://eur-lex.europa.eu/legal-content/FR/TXT/?uri=CELEX%3A32014L0068&qid=1616077985958On May 15th, 2014, the new Pressure Equipment Directive (PED) has been adopted by the European Parliament and the Council of the European Union. Some essentials of the former PED remain unchanged such as the scope, the "Essential Safety Requirements" (Annex I), the "Conformity Assessment Tables" (Annex II), and the CE marking requirements. However, concerning changes, the new PED defines the obligations and responsibilities of importers (Art.8) and distributors (Art. 9). It is also quite noticeable that the Art. 3, §3 of the 97/23/EC Directive, defining the exclusions of the PED’s Technical Requirements, becomes the Art. 4, §3 under the 2014/68/EU Directive.

The PED (Pressure Equipment Directive) concerns the design, manufacture and conformity assessment of pressure equipment. It applies only to products from DN32 and 0.5 bar upwards. Art. 4, §3 sets out certain exclusion rules.

Fluids passing through these devices are classified into 4 groups according to 2 criteria: Liquid/gas; Hazardous/non-hazardous. Each group has its own risk classification scale ("risk categories") which will determine the levels of production control required.

1 - Scope

The PED applies to the design, manufacture and conformity assessment of pressure equipment and assemblies with a maximum allowable pressure (PS) greater than 0,5 bar such as: vessels, pressurised storage containers, heat exchangers, steam generators, boilers, industrial pipes, safety devices, pressure accessories, valves and fittings.

Equipment excluded from the PED (CE marking prohibited):

- Equipment with PS < 0,5 bar (Art. 1 §1)

- Valves and fittings < DN32 (Art. 4 §3)

DN: Nominal size

PS: Maximum allowable pressure

TS: Maximum/minimum allowable temperature

2 - Classification & fluid groups acc. to Regulation n°1272/2008 (2014/68/EU Directive, Art.13,§1)

Fluids means gases, liquids and vapours in pure phase as well as mixtures thereof. Fluids may contain a suspension of solids.

Group 1 - Hazardous fluids

Explosive, extremely flammable, highly flammable, flammable (max. allowable temp. above flashpoint), pyrophoric, very toxic, toxic, oxidizing.

Liquids example: fuel

Gases example: natural gas

Group 2 - Non hazardous fluids

Other fluids not referred to in Group 1.

Liquids example: water

Gases example: natural gas

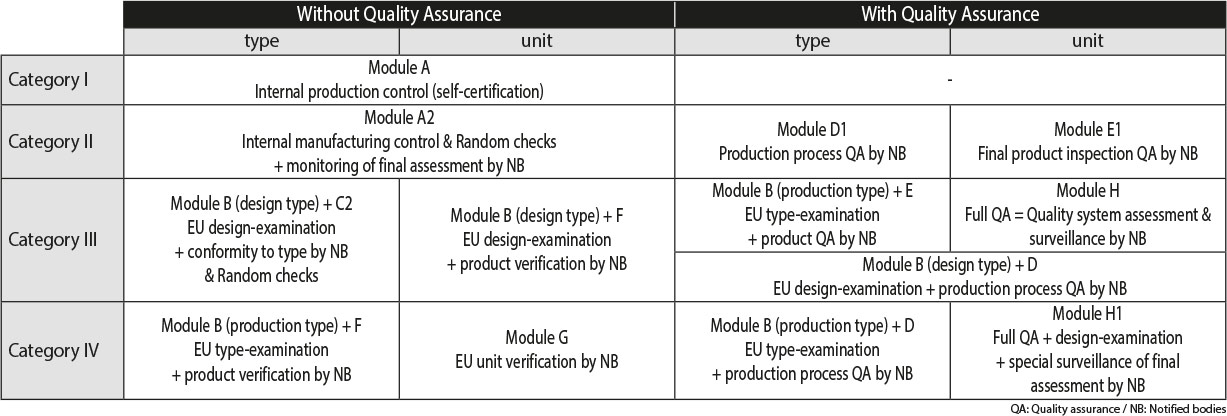

3 - Risk categories (Annex II)

Risk category IV only applies for safety devices.

4 - Conformity assessment procedures (Art. 4 + Annex III)

Conformity assessment procedures (Art. 4, Annex III) groups together categories I to IV and highlights the assessment procedures to be followed depending on the product category.

5 - Notified bodies

List of notified bodies operating with our manufacturers under 2014/68/EU Directive:

What is ATEX Directive - 2014/34/EU?

Access Multilingual Directive :

https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32014L0034

What does ATEX mean?

ATmosphère EXplosive. This directive determines the essential characteristics of equipment for use in an explosive atmosphere.Directive on equipment and protective systems intended for use in potentially explosive atmospheres (ATEX - ATmosphères EXplosibles). There are 2 ATEX Directives: Directive 2014/34/EU concerns equipment (products) and Directive 1999/92/EC relates to the minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres.

Potential explosive atmospheres exist when air is mixed, under atmospheric conditions, with flammable substances in the form of gases, vapours, mists or clouds of dust which can entirely spread combustion when exposed to a source of ignition. The new 2014/34/EU Directive defines the obligations and responsibilities of importers (Art.8) and distributors (Art. 9). Moreover, the Directive establishes that every operator shall keep records of any supply of ATEX equipment for 10 years (Art. 11).

What types of valves are covered by the ATEX directive?

The Directive (Art. 2, §1) and the "ATEX 2014/34/EU Guidelines" (§38) determine that equipment and simple piping elements such as fittings, manual valves, non-return valves, strainers, pressure reducers, safety valves, steam traps… are out of the scope of the directive because they do not have their "own potential source of ignition". Therefore, they do not need certification to be installed in hazardous areas. Only actuated valves (whether electric or pneumatic) and sight glasses (because of the mechanical resistance of their glass part) are subject to the ATEX Directive. However, regarding manual valves and other simple piping elements, a risk analysis should be carried out to ensure the compatibility of the valve with the explosive environment. This involves, for example, ensuring that the electrostatic risk due to the plastic elements of a valve is eliminated.

Can a manual valve be ATEX?

Manual valves do not fall within the scope of the directive.

Manual valves are simple mechanical products with no ignition source of their own. The electrostatic risk generated by the flow of fluid is not a source of ignition specific to the valve.

They can be used in ATEX zones 1, 2, 21 and 22, in accordance with the manufacturer's instructions and after checking the risk analysis.

Marking is not authorised. A Declaration of Conformity with the Directive may not be issued. Entry into force 2016.

is not authorised. A Declaration of Conformity with the Directive may not be issued. Entry into force 2016.Can there be an ATEX certificate for a manual valve?

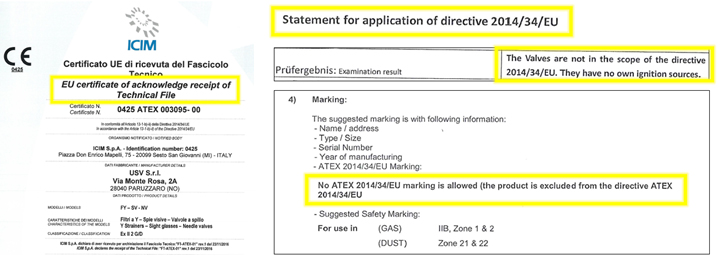

NO, because manual valves are outside the scope of the ATEX directive. However, depending on the supplier, we can provide :

- A document certifying that a technical file has been submitted to a notified body. This file constitutes a risk analysis by the manufacturer and demonstrates the compatibility of the manual valve in an ATEX zone in relation to its construction (example 1). Please note: the notified body is not responsible for checking the file, but exclusively for recording and storing it for a period of 10 years.

- A declaration in relation to the ATEX directive stating that the product is outside the scope of the directive (example 2).

Can an actuated valve be ATEX?

Actuated valves fall fully within the scope of the Directive.

It is the assembly that is certified, and certification is unitary.

Assembling ATEX-compatible/certified components does not automatically mean that the assembly is ATEX-compatible/certified.

Documentation must be kept for a period of 10 years.What is the ATEX zone classification?

The Directive concerns gassy mines and surface industries for the two risk atmospheres: presence of gas or presence of dust. It is up to the operator to define the zones in which an explosive atmosphere can occur using the following classification according to 1999/92/EC Directive:

What does the ATEX marking mean?

What is Low Voltage Directive - 2014/35/EU?

Replaces Directive 2006/95/EC.

Its aim is to ensure that electrical equipment on the market meets the requirements guaranteeing a high level of protection for the health and safety of persons:

Internal manufacturing control

Technical documentation

CE marking and EU Declaration of Conformity (DOC)This directive applies to electrical equipment intended for use with a nominal voltage of between 50 and 1000 V for alternating current and 75 and 1500 V for direct current.

Source:

https://eur-lex.europa.eu/legal-content/FR/TXT/?uri=CELEX%3A32014L0035&qid=1616079636399What is Gas Appliances Regulation - 2016/426/EU?

Replaces Directive 2009/142/EC.

The former Gas Directive has been transformed into the "Gas Regulation" and applies to appliances using gas other than appliances "specifically intended for use in industrial processes used in industrial establishments".

This regulation does not affect the obligation imposed on Member States to adopt measures concerning the promotion of the use of energy from renewable sources and the energy efficiency of buildings, in accordance with Directives 2009/28/EC, 2010/31/EU and 2012/27/EU.

Source:

https://eur-lex.europa.eu/legal-content/FR/TXT/?uri=CELEX%3A32016R0426&qid=1616080249774What is Machinery Directive - 2006/42/CE?

It applies to our actuated valves.

General Principles

The manufacturer of a machine or his authorised representative must ensure that a risk assessment is carried out to determine the health and safety requirements that apply to the machine. The machine must then be designed and constructed taking into account the results of the risk assessment.

Through the iterative process of risk assessment and risk reduction referred to above, the manufacturer or his authorised representative:

- determines the limits of the machine, including its normal use and any reasonably foreseeable misuse,

- identify the hazards which may arise from the machinery and the associated dangerous situations,

- estimate the risks, taking into account the seriousness of possible injury or damage to health and the probability of such injury or damage,

- assess the risks, with a view to determining whether risk reduction is necessary, in accordance with the objective of this Directive,

- eliminate hazards or reduce the risks associated with hazards by applying protective measures.Source :

https://eur-lex.europa.eu/legal-content/FR/TXT/?uri=CELEX%3A32006L0042&qid=1616074910815

DOP for which products?

Harmonised Conditions for the Marketing of Construction Products - EU Regulation No. 305/2011/EU.

The purpose of this regulation is to provide a regulatory (legal) framework for construction products that are not yet governed by a European directive, and to enable CE marking of these same products.

The "Declaration of Performance" (DOP) introduced by the CPR (Construction Products Regulation) must refer to harmonised standards for construction products. For there to be a DOP, there must first be a harmonised standards framework. For example, no harmonised standard yet exists for "drinking water" valves, so the DOP does not apply.

It should be noted that not all products that form part of the construction of a building are, strictly speaking, construction products and/or are not linked to harmonised standards.

We do not sell construction products, and very few products in our range are explicitly covered (lifting stations). Furthermore, any product already covered by the PED or another directive is outside the scope of the DOP, which refers to the CPR.According to the recommendations of the CEIR (The European taps and valves association), we consider that our products do not need to comply with the CPR regulation and we therefore do not draw up a DOP.

What is Regulation 1935/2004/EC?

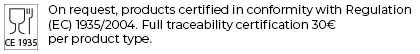

Regulation EC 1935/2004 applies to materials and articles intended to come into contact with foodstuffs. It therefore applies to all food equipment.

Please note: It does not apply to drinking water distribution networks.

The materials used in the manufacture of food fittings must be traceable to ensure that they are compatible with foodstuffs. As with the FDA (U.S. Food and Drug Administration), particular attention is paid to elastomers and plastomers and the risks of migration of chemical substances.

For valves and fittings, the manufacturer or importer draws up an EU Declaration of Conformity (DOC) to EC Regulation 1935/2004 setting out the test results and affixes the CE mark to the equipment.EC Regulation 1935/2004 is supplemented by another EC Regulation, No. 2023/2006 "Good Manufacturing Practice", which applies to manufacturers of food equipment, including valves.

Sources :

https://www.economie.gouv.fr/dgccrf/Fiche-generale-relative-a-la-reglementation-des-maThe traceability service is described on page 22 of our catalogue :

What is FDA?

The Food and Drug Administration (FDA) is the US government agency that regulates and enforces consumer protection laws on issues related to the food, cosmetics and medical/pharmaceutical markets.

The requirements for the food and medical/pharmaceutical sectors are not the same.

In the food sector, the FDA has drawn up positive lists of substances and materials authorised for contact with food. FDA certification therefore relates to the materials making up the product, but never to the product in its entirety (e.g. seat of butterfly valves). There is no FDA certificate as such, but a valve manufacturer can provide a self-declaration showing the use of compatible materials referenced on the "positive lists".

As with CE 1935, particular attention is paid to elastomers and plastomers.What is REACH - Regulation 1907/2006/EC?

This European regulation aims to make the manufacture and use of chemical substances in European industry safer, in order to protect human health and the environment. The aim is to make the entire industrial chain accountable and to ensure that information on the nature and risks of the substances used is transparent from the manufacturer to the end customer.

The abbreviation stands for :

- Registration of all substances manufactured or imported in volumes greater than 1 tonne per year;

- Evaluation of testing proposals, registration dossiers and substances;

- Authorisation, for substances of very high concern;

- Restriction, to manage the risks associated with other CHemical substances.

In concrete terms: The substances of greatest concern, identified on a candidate list of SVHCs (Substances of Very High Concern), are subject to authorisation so that they can be controlled. Chemical substances on this list that are manufactured in or imported into the EU must be declared and registered in a dossier that includes an assessment of the risks to health and the environment, in accordance with the following rules:

Article 33 of REACH requires manufacturers and importers of these substances to inform their customers if an article contains a substance on the candidate list in a concentration of more than 0.1% (by weight). This obligation to provide information is reflected in a DOC.

Article 7.2 specifies that the producer/importer of articles must notify ECHA (the European Chemicals Agency) if the following 2 conditions are met:

- A concentration of more than 0.1% in the article of the substance included on the SVHC list

- The volume of the substance produced or imported exceeds 1 tonne per year.

Registrations are submitted to the ECHA, which keeps a list available online to guarantee access to information for all market players.

Source :

Guide REACH INERIS

https://ec.europa.eu/environment/chemicals/reach/reach_en.htm

https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32006R1907&qid=1642599525906

What is RoHS - Directive 2011/65/EU (RoHS 2)?

The European RoHS Directive (Restriction of Hazardous Substances in electrical and electronic equipment), applied since July 2011, aims to limit the use and maximum values of ten hazardous substances in electrical and electronic equipment (EEE) to protect the environment and human health.

Which products are affected? Any product with an electrical or electronic component must comply with this Directive, unless specifically excluded. EEE is equipment that uses electrical/electromagnetic currents designed for use at up to 1,000 volts alternating current and up to 1,500 volts direct current.

For more details on the scope and exclusions, see Article 2 and Annex I of the Directive.

RoHS3 has been applied since July 2019 and includes 4 additional restricted substances.If the product is in the scope of RoHS, CE marking is mandatory.

What is Waste Framework Directive (2018/851/EU)?

This Directive establishes basic concepts for waste management in the EU.

It prioritises the order of treatment in five stages, as shown in the infographic.

Prevention is preferred and sending waste to landfills should be the last option. Producer responsibility and the "polluter pays' principle.Since the Directive came into force, reuse and recycling targets have been set in five-year stages up to 2035, and are becoming stricter.

If this rate was 50%, it will be 65% by 2035.

Waste is classified as hazardous and non-hazardous. As hazardous waste represents a greater risk to the environment and human health, it is subject to a stricter framework. Traceability must be ensured from production through to the final waste management stage. This traceability is also based on the registration of substances on the SVHC list with ECHA, which provides free online access to this information.Each Member State must define its waste management plan in accordance with the Directive.

Source:

https://environment.ec.europa.eu/topics/waste-and-recycling/waste-framework-directive_en

https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex:32018L0851

https://ec.europa.eu/environment/pdf/waste/plans/2012_guidance_note.pdf

What is UKCA - Product marking for the UK?

Following Brexit, CE marking will be replaced by UKCA (UK Conformity Assessed) marking in the UK from 1 January 2025. Since 1 January 2021, the new marking can already be used. This marking is not recognised in the European Union.

The technical requirements and assessment processes for UKCA marking remain largely the same as for CE marking. As with CE marking, a declaration of conformity for products bearing this new marking is also compulsory. Assessments must be registered with "Notification Bodies" (now Approved Bodies or ABs) based in the UK. Northern Ireland is excluded from this process.

At present, after several postponements, the legislation provides for the UKCA mark to come into force for products placed on the market from 1 January 2025. Products placed on the market before this date are exempt from this requirement.

The government is considering the possibility of introducing a derogation whereby a label affixed to the product or to a document accompanying the product could suffice until 31 December 2027.Source:

https://www.gov.uk/guidance/using-the-ukca-marking

https://www.gov.uk/guidance/using-the-ukca-marking#technical-documentation

What does Firesafe mean?

A "fire-safe" valve has a specific construction that guarantees the valve's tightness in the event of fire. A "fire-safe" valve must not explode, and must remain tight and operable when exposed to fire for a certain length of time. For ball valves, this is made possible by the addition of graphite gaskets in the body and gland pack.

Various Firesafe standards can be chosen as references by customers:

API 607 version 7 2016, what has changed?

The standard no longer allows extensions according to the main families of materials (ferritic, austenitic, duplex). If a range is covered by tests on ferritic valves, the coverage can’t be extended to austenitic or duplex materials. A test by material will have to be carried out. Thus, a valve tested in steel (austenitic) no longer validates a valve tested in stainless steel (austenitic).

What does NACE certify?

The National Association of Corrosion Engineers is an organisation that sets criteria and standards for material requirements and guarantees anti-corrosion surface treatment, thereby helping to make installations and their environment safer. NACE certification means that the product complies with these criteria. There is no specific NACE certificate; it is mentioned on the 3.1 certificates (see pricing conditions in our price list, as this certificate is subject to a fee).

In the petroleum sector, the main standards are NACE MR0175 (extraction and production) and NACE MR0103 (refining), which detail the behaviour of metals in highly corrosive environments with the presence of H2S (hydrogen sulphide, a flammable and highly toxic gas).

Drinking water - Which certificate for which market?

On the European market, there are certificates for drinking water which are specific to each country: ACS (France), WRAS (UK), PZH (Poland), DVGW (Germany), KIWA (Netherlands), Aviz Sanitar (Romania). Harmonisation at European level is currently being introduced.

At the instigation of the World Health Organisation, a draft revision of Directive 98/83/EC on the quality of water intended for human consumption is underway. The proposal is to introduce a specific Article 10a for Materials in Contact with Drinking Water (MCDE) based on work carried out by the 4MS, 4 Member States - France, Germany, the Netherlands and the UK (before Brexit). Among other things, this work defines a positive list of authorised alloys, and stricter requirements than EN-12165 on the composition of these alloys: less lead, less nickel and fewer impurities. Products using alloys (brass, stainless steel, bronze) will soon be the only ones eligible for an ACS.

Testing of metallic valves - Which regulation and standards for valves and their leakage rate ?

Different standards may be referred to regarding metallic valve testing and leakage rating. Two main standards are most commonly used :

EN 12266-1 and API 598. Where any of those 2 standard is specified as a normative reference in a product, its performance shall be considered according to the requirements of that standard.EN 12266-1

Industrial valves - Testing of metallic valves - Part 1: Pressure tests, test procedures and acceptance criteria - Mandatory requirements

The EN 12266-1 specifies the mandatory test requirements, test procedures and acceptance criteria for production testing of industrial valves made of metallic materials. Safety devices are not in the scope of the EN 12266-1. The prescribed tests may also be used as type tests, or acceptance tests.

The following requirements are considered : Shell resistance, shell tightness, seat tightness and closure resistance. The Annex A of the standard defines the test procedures and acceptance criteria.

1 - Test pressure & medium

- Shell resistance (P10), shell tightness (P11) and closure resistance (P20): test pressure = 1.5 x PS (max. allowable pressure at ambient temp.). Shell resistance & tightness must be tested with liquid unless otherwise agreed by the parties.

- Seat tightness (P12): the test pressure shall be at least 1.1 x PS (max. allowable pressure at ambient temp.). If the test medium is a gas,

the test pressure shall be the lower between 1.1 x PS and 6 bar (±.1 bar).

2 - Duration of test (Tables A.2 & A.4 - Minimum duration of test)

(A) Check the pressure resistance of the closure if the valve is used as the sole means of isolation between the contents of a pressure equipment

and the downstream part not designed to withstand the upstream pressure.

(B) If the test medium is a gas, the test pressure shall be the lower between 1.1 x PS and 6 bar (±1 bar).

(C) Shell resistance must be tested with liquid unless otherwise agreed by the parties.3 - Acceptance criteria

- For the shell resistance, shell tightness and closure resistance tests:

- Whether the test is performed with a liquid or a gas, no visible leakage is allowed.

- For the seat tightness test, the selection of rates A to G is specified in the corresponding valve product standards.

- The leakage rates measured during the test period shall not exceed the rate specified in the following table (Table A.5 - Maximum allowable seat leakage for each leakage rate - in mm3/s) :

Note 1 - Leakage rates apply only for discharge at room temperature.

Note 2 - "No visually detectable leakage" means no visible seepage or formation of drops or bubbles.

If leakage rate measurements are made by automatic means, they must be qualified by the manufacturer's quality system.API 598

Valve Inspection and Testing.

1 - Scope

The API 598, from the American Petroleum Institute, provides industry standards for valve ratings and valve leakage allowance. The standard is currently in the 10th edition (2016). It covers inspection, examination, and pressure test requirements for resilient-seated, nonmetallic-seated, and metal-to-metal-seated valves of the gate, globe, plug, ball, check, and butterfly types.

API 598 specifies the following tests and examinations :

- Shell resistance tests to validate the pressure containing structures of the valve.

- Backseat tests to verify the leakage through the sealing of the stem.

- Low-pressure & high pressure closure tests to verify the leakage through the closure mechanism.

2 - Pressure tests (Tables 1 & 2 - Pressure tests according to valve type)

(A) The backseat test is required for all valves, except for bellows seal valves, that have the backseat feature. / (B) Also applies to trunnion mounted ball valves.

The test medium shall be air, inert gas, kerosene, water (or a noncorrosive liquid with a viscosity no higher than that of water) at temperature between 5°C and 50°C. The test pressures depend on the valve type, the pressure class and the DN of the valve according to tables 3 & 4.

3 - Duration of test (Tables A.2 & A.4 - Minimum duration of test)

(A) In seconds. The test duration is the period of inspection after the valve is fully prepared and is under full pressure. / (B) For valves with backseat feature. / (C) API 594.

4 - Acceptance criteria

- For the shell and backseat tests:

- Whether the test is performed with a liquid or a gas, no visual detectable leakage is permitted.

- For the low-pressure closure test, the table 6 defines the maximum allowable leakage rates for closure tests.

(A) For valve size above DN500 (NPS20), please refer to the API 598 standard for rates values. / (B) For the liquid test, 1 mL is considered equivalent to 16 drops. / (C) There shall be no leakage for the minimum specified test duration (see Table 5). For liquid test, 0 drop means no visible leakage. For gas test, 0 bubbles means less than 1 bubble.

Fugitive Emissions / TA LUFT

Fugitive emissions are chemicals or a mixture of chemicals in different states that represent an unwanted leak from equipment on an industrial site. In the petrochemical industry, industrial valves are considered to be the main sources of fugitive VOC (Volatile Organic Compounds) emissions. Various standards propose procedures (type tests or production tests) designed to characterise and qualify the performance of valves or valve stem sealing systems. These standards differ in terms of the test methods used, but all have the same objective: to guarantee the reduction/elimination of emissions of dangerous particles into the atmosphere. They are recognised to a greater or lesser extent in different countries and professions.

Here are the main references:

- Standard ISO 15848-1&2

- BS EN 15445:2008 standard

- The VDI 2440 specification for TA Luft

- API 622 standard

- MESC Shell SPE 77-300 and SPE 77-312

To meet different market requirements, manufacturers can design their products to meet one or more of these standards.What is SIL?

The "Safety Integrity Level" gives the safety integrity level of an electrical or electronic product in accordance with standard IEC EN 61508. The level of risk reduction is expressed in 4 levels (SIL 1 to SIL 4). The SIL is defined by an international commission.

Can a product be SIL3?

An isolated product cannot be SIL3 but it can be SIL3 capable.

To be SIL3, the standard requires redundant installations. In the world of valves, this means that valves must be doubled in parallel or in series, depending on whether you want to guarantee opening or closing.The International Electrotechnical Commission defines the different SIL levels for electric and electronic devices as follows:

What does IP mean?

Degree of protection provided by the product enclosure; marked on the product in the form of an "IP" code.

Example: IP 54 would indicate a dust protected (first digit 5) piece of equipment which is protected against splashing water (second digit 4).

Marine approvals

Marine approvals are documents commonly required in the marine sector to guarantee a necessary level of quality, specific to the constraints associated with the use of products in these applications.

There are a number of specialist bodies recognised in the industry. The main international bodies are : Bureau Veritas, Lloyd's Register, DNV-GL and ABS (American Bureau of Shipping) for Western markets, and ClassNK (Nippon Kaiji Kyokai) and CSS (China Classification Society) for Asian markets.There are different types of approval:

Type Approval is a product design approval specific to each organisation (Lloyd's, BV, DNV, etc.). A manufacturer can have as many as the number of products it wishes to certify. It is a type approval (linked to the design of the product) which has been defined according to specific specifications.Marine Recognition BV Mode II (from Bureau Veritas) is a company certification that refers to quality management. It is a kind of specific ISO 9001 that is recognised in the marine (and marine insurance) world.

These bodies are also often present on the market as notified bodies for various European directives. For example, any Lloyd's Register certificate (ISO, CE, etc.) should not be confused with the concept of marine "Lloyd's Register type approval", which is an approval attesting to marine compatibility issued by Lloyd's.ANSI, API, ASTM and ASME - what's the difference?

ANSI

The "American National Standard Institute" is an organisation that oversees and consolidates the development of standards for products, services, processes, systems and employees in the United States. ANSI is to the USA what EN is to Europe and ISO is to the world.API

"The American Petroleum Institute" is the standards body for the oil and gas industry in the USA. Because of the predominance of American companies in this market, API standards have global recognition. Pipe and valve diameters are expressed in NPS (Nominal Pipe Size - in inches/inch). There are a large number of reference standards, such as API 602 for compact Gate, Globe and Check valves for DN up to 4″ and for pressure classes from 150 to 1500. Criteria for design and construction are detailed, as well as materials and TRIM designations and other technical specifications.

API has set up an inspection programme which allows certificates to be issued and API monograms to be affixed to products.ASTM

"The American Society for Testing Materials is a standards organisation for products, materials, systems and services. One material has several designations under the DIN or ASMT standards ( ). Given the influence of the USA on the oil market, these standards and ratings are predominant in the Oil & Gas sector and often used as a reference in Europe.ASME

The American Society of Mechanical Engineers promotes collaboration and the exchange of knowledge and skills in the field of scientific research into mechanical engineering. It draws up standards for several types of products, including compressors, pressure vessels and piping.EN 1074 standard

This European standard, which has been in force since 2000, concerns valves for supplying water intended for human consumption.

It is divided into 8 parts:

- Test procedures (design and conformity assessment)

- Mechanical resistance

- Tightness

- Endurance

- Materials

- Marking, which must be durable and contain a certain amount of information, such as DN, body material, PS, product identification and year of manufacture.