Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

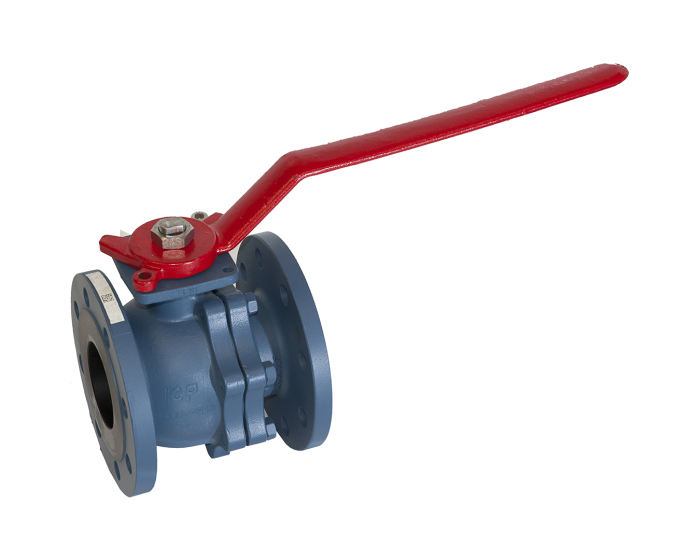

ICP range split body valves: what are the uses and advantages'

In which areas are the ICP range valves used'

ICP split body valves have numerous applications in the field of chemical products, the petrochemical industry, as well as in hydraulic installations, heating systems, and air and water distribution systems.

What do they look like'

These are full bore two-piece valves. Bodies are in A216WCB carbon steel or CF8M stainless steel, balls are in CF8M stainless steel, and seats in second generation PTFE (TFM 1600). Diameters range from DN15 to DN200, and the valves are fitted with flanged connections of various types: RF PN16/40, ANSI 150, or ANSI 300.

Main features of the ICP split body valves

Split body valves enjoy a great number of advantages and specific equipment:

- Locking device

- ISO 5211 pad for direct mounting of an actuator

- Anti-blowout stem, with conical design for tightness in case of fire

- Graphite gland packing and FKM gasket, also ensuring tightness at stem

- Antistatic device

- Spiral-wound gasket at seat (maintains tightness if temperature and pressure fluctuate)

- decompression hole on ball (preventing blocking in open position)

These valves also have various face-to-face length, depending on the different models:

- EN 558 series 27 (DIN3202 F4 and F5)

- EN 558 series 3 and series 12

- EN 558 series 4

Another important element is the TFM 1600 (second-generation PTFE) seat, which adds multiple benefits to the split body valve:

- Enhanced seal

- Larger capacities in regard to pressure and temperature

- Better resistance to wear and tear

- A smaller operating torque and a smaller number of particles created.

Different models tolerate different temperatures, (from -50 °C up to +230 °C for example). The maximum operating pressure ranges from 16 up to 50 bar with some of these valves.

Syveco also offers two items available as options: a spare gearbox and a spare stainless-steel lever.

Last, our ICP brand valve range enjoys a great number of certifications:

- Fire safe according to the ISO 10497:2004 standard (tightness in case of fire)

- Fugitive emissions according to the ISO 15848-1 standard

- Compatibility with ATEX zones

- NACE MR0175 certification (ISO 15156), for RF ANSI 150 and 300 flanged valves (materials chosen for their anti-corrosion characteristics, for H2S containing atmospheres, in oil and gas environments for example).