Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

Check valves for water

Check valves: what is their purpose?

Installed on hydraulic systems or on water distribution networks, check valves are used to protect other items such as pumps or pipes for example. How? Check valves are unidirectional elements, which means that the fluid running through them goes in one direction only. If a backflow occurs, an obturator (swing plate, disc, ball) closes automatically, preventing the liquid from flowing back. Using check valves is then a solution to a number of potential damages, such as water hammers caused by the backflow speed, a broken pump turbine, or more simply accidental draining of a tank or a pipe.

Check valves are widely used with different types of pipes, such as hydraulic systems, heating systems, water supply networks, sewage and residual water networks, industrial sludge treatment systems.

Syveco offers different sorts of check valves.

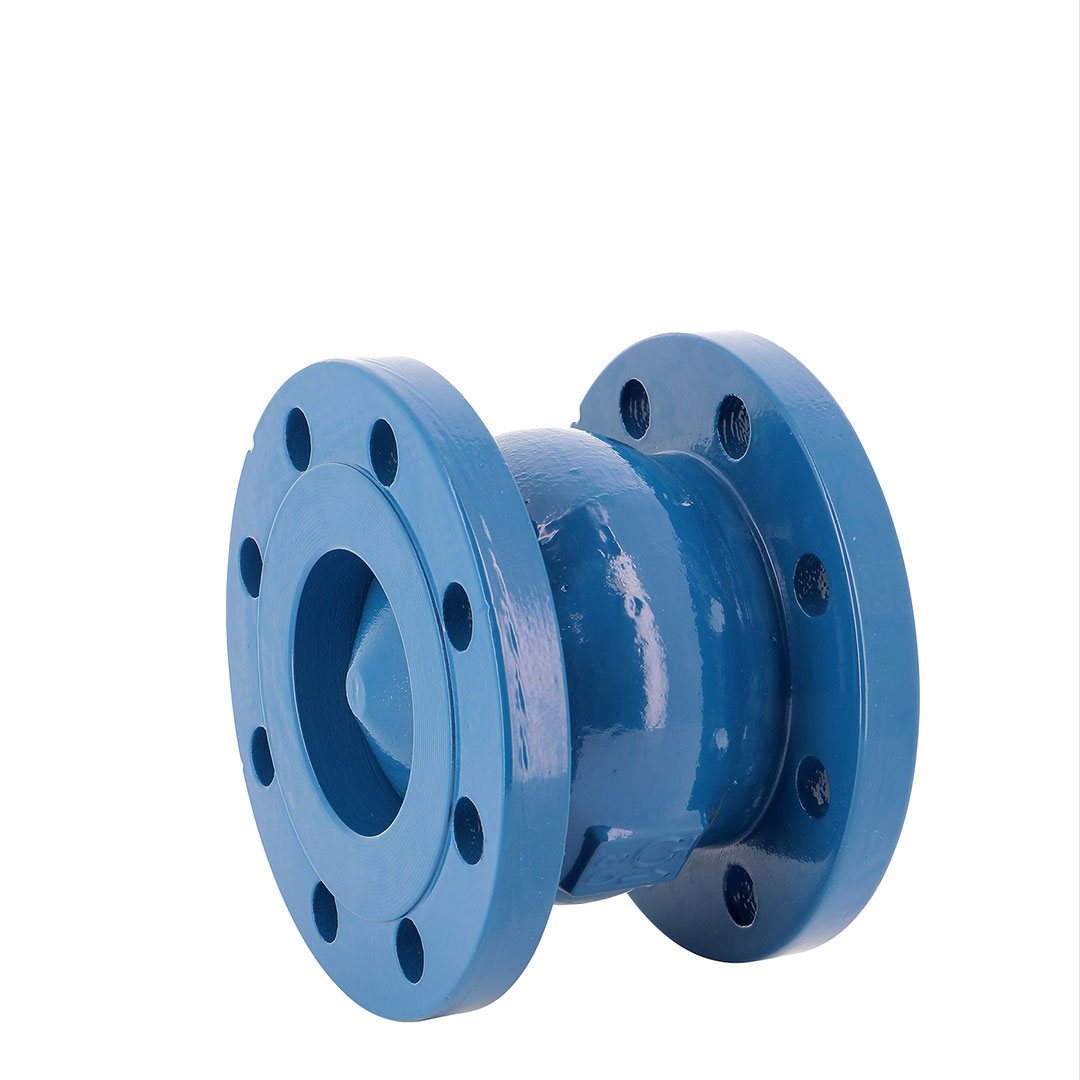

Cast iron spring check valves

Cast iron spring check valves, also known as nozzle check valves or axial check valves, are used with clean water. Bodies are in EN-GJL-250 grey iron or EN-GJS-400-15 cast iron, and are entirely coated with epoxy paint. Discs can be in stainless steel or in epoxy-coated cast iron. These valves are provided with a stainless-steel spring, allowing the device to be mounted in any position and facilitating the quick closing of the obturator. This prevents the flow from gaining speed. The spring cast iron check valve main advantage is low pressure loss. This is due to two elements: the spherical inner design of the body, and the disc shape, improving the valve hydro dynamism. It is also a quiet valve.

Note: one of Thermador International’s references is ACS-certified and can be used on drinking water circuits.