Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

Y-strainers for industry and water

Y-strainers: what are they for?

Y-type strainers are named after their shape. They are used as filters, preventing dirt and particulates to move inside piping systems. They are set upstream of devices and fixtures such as valves, traps, or pumps.

The mesh is of different size depending on the models. It retains solid particles thus helping to protect equipment from being damaged.

Moreover, the pressure loss is minimal as the fluid goes through the filter normally, without being blocked or forced to slow down.

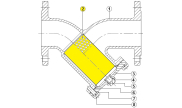

Different parts of the Y-strainer

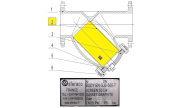

The Y-strainer is made up of several parts, the most important ones being the body, the screen (mesh), and the bolted bonnet with draining cap.

Special characteristics of the Y-strainer

A Y-strainer can be set on in a vertical or horizontal position on a circuit, with the screen pointing downward in order to catch all the dirt and particles. It is important to think about cleaning or draining from the waste collected. The draining cap and the removable screen make cleaning easy.

In which type of sectors are Y-strainers used?

Y-strainers are used in a lot of different fields, depending on the type of product: watering, irrigation for example, but also steam and high-temperature circuits, high pressure, gas circuits, oil industry...

Syveco’s offer

Syveco offers various models of Y-strainers. They can be in carbon steel, stainless steel, cast steel, or cast iron with epoxy paint. They are fitted with different types of connections: RF PN10/16, PN 40, ANSI 150 or ANSI 300, BSP or NPT threaded, or socket welded. The flanged filters length depends on the EN 558 series 1 (DIN 3202-1 F1 – NF 29354) standard.

On the removable stainless-steel screens, the mesh can have different sizes, ranging from 0.15mm to 5mm depending on the products and uses.